Ethium Technology

Chemistry

Latest Lithium Iron Phosphate [LiFePO4]

Energy Dense

- 300% more energy dense than lead acid

High Efficiency

- Lower system level battery resistance

- Less energy wasted as heat for equalization charging

- Cells at the perfect voltage multiplier (3.2 V)

High Safety

- Utilizes UL 1642 compliant cells that are extremely robust to thermal runaway

- Emits no flammable gases during charging and has no battery acid exposure

High Reliability

- Lasts up to 4,000 charge/discharge cycles with 80% residual capacity

- Virtually no memory effect

- Resilient to deep discharge (90%)

Wide Range of Temperature Operation

- Storage temperatures from -40 to 85°C

- Operating temperatures from -20 to 60°C

Fast Charging

- Capable of 1.0 C (1 hour full charge) charge and discharge rate

Electronics and Software

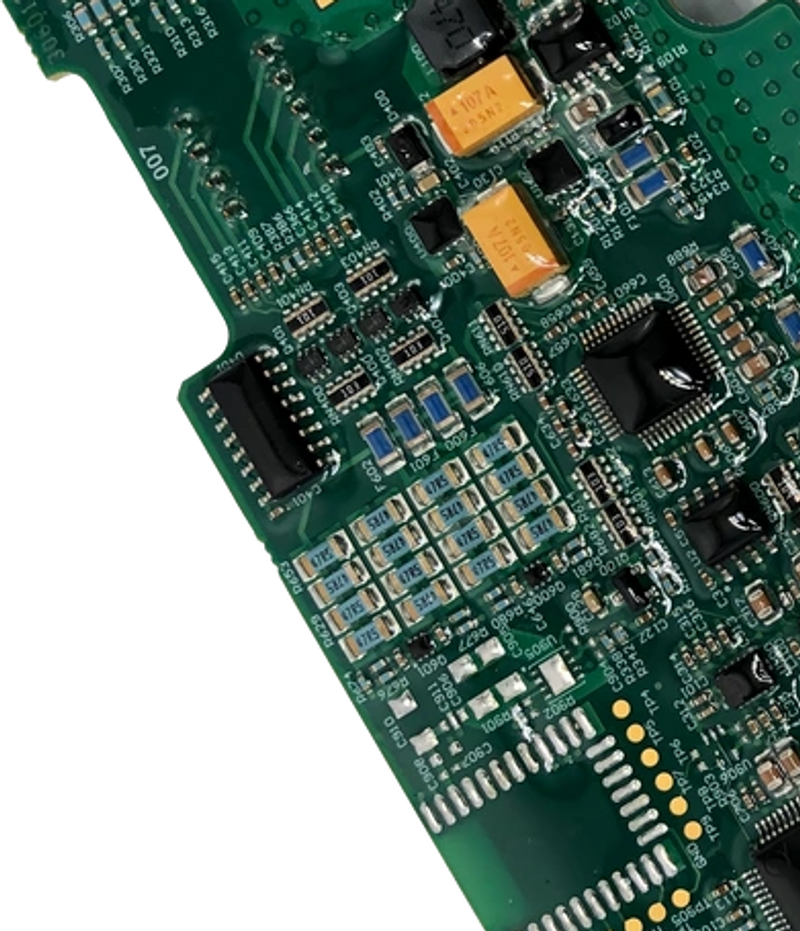

BMS Electronics

- Solid state power electronics provide electronic fusing capability

- BMS has the ability to rapidly detect and disconnect during a system level short circuit in under 75 microseconds

Software

- Accurate SOC estimation and temperature rise awareness with in situ thermal model

- Complete cell control (voltage, temperature, battery health, and current flow)

- Advanced active cell balancing measures and controls cell voltages within cell banks and removes any extra energy from cells with a higher voltage

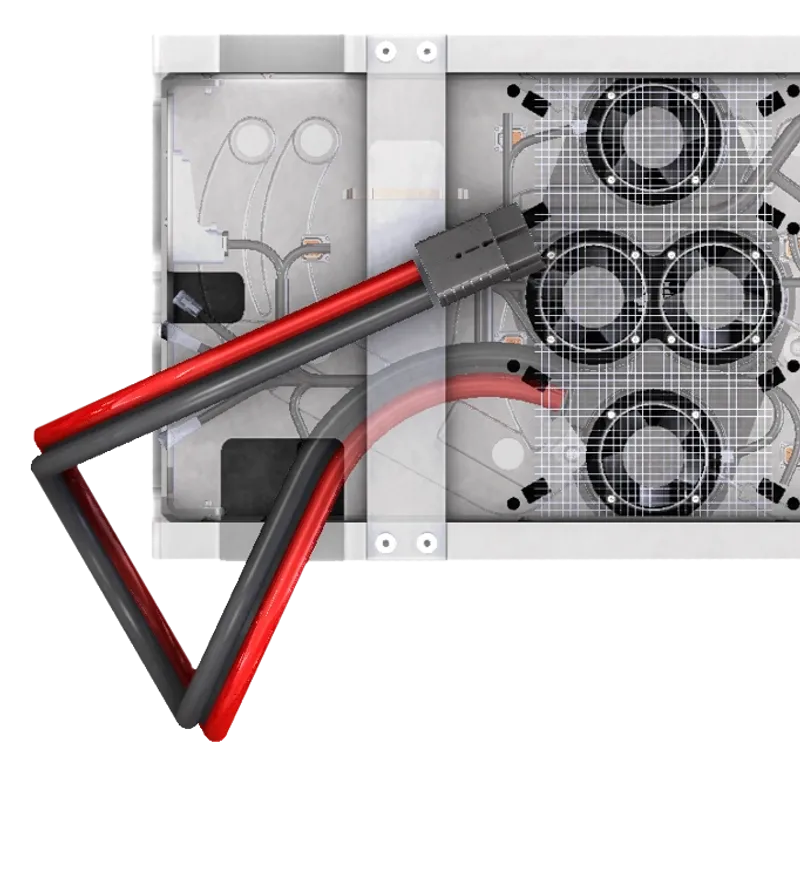

Active Voltage Control (AVC)

- Accelerates charging with continuous control of alternator voltage

Data Acquisition System (Optional)

- Integrated DAQ system for warranty and diagnostics

Construction

Cell Based (Sealed Cylindrical Cells)

- Modular for modifying voltage and capacity

- Extremely safe with built in burst disk and individual cell fusing

- Prevents failure propagation and thermal runaway

Sandwiched Honeycomb Structure Cell Packaging

- Energy dense, lightweight, and heat conducting with top mounted connections

- PCB sandwich design with ultrasonic wire-bonding technology

Sealed and Corrosion Resistant Enclosure

- Modules made from aluminum and engineered plastics to meet the IP67 standard

- Powder coated steel upper level assembly

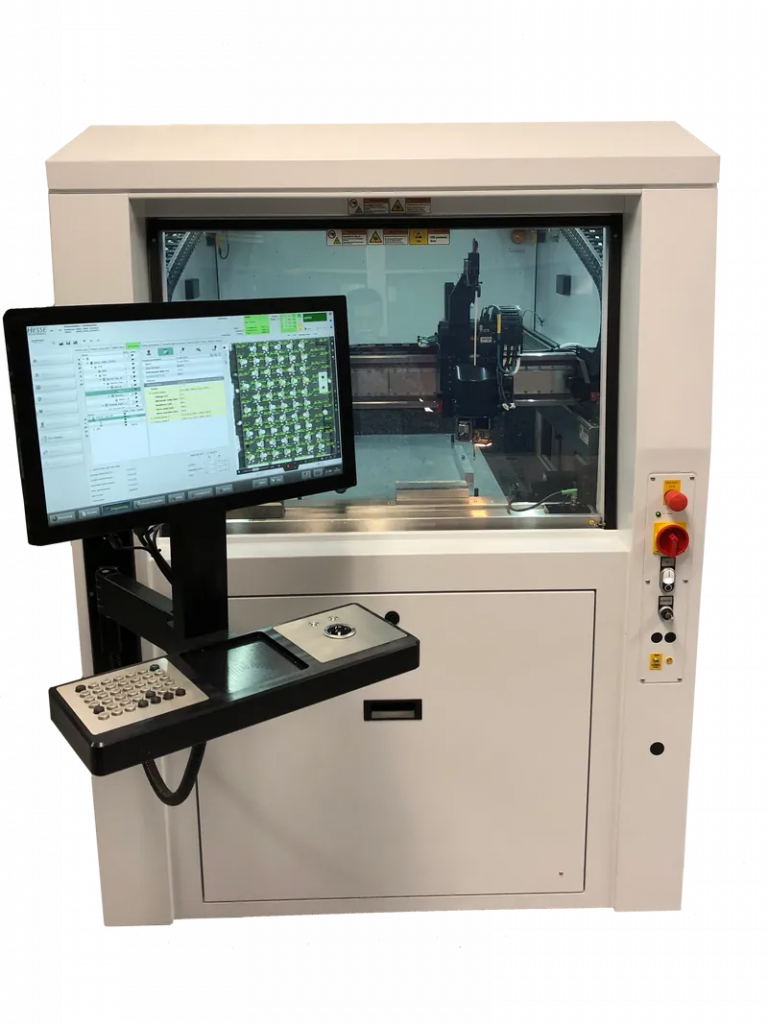

Manufacturing

Fully Automated Assembly

- Automated production line for high production capacity

- Less human-to-part contact to minimize human errors

State of the Art Wire-Bonding

- Highly precise and repeatable connections, superior to traditional welding or hardwiring

- Easy to automate with single orientation assembly

In-house Electronics Manufacturing

- ISO 9001 certified facility with state of the art Surface Mount Technology (SMT)

- 30 years of vertically integrated design and manufacturing experience in electronic control devices for industrial applications

100% Automated Testing and Cell Balancing

- All cells are fully charged and tested

- Each pack is tested at the end-of-line to meet performance and safety requirements

Designed and Manufactured in the USA

Compatibility and Validation

Compatibility

- Completely compatible with existing equipment

- Drop-in-place solution (voltage, chargers, inverters)

- Designed to fit most current battery compartments

Testing

- Thermal, vibration, shock, electrical/EMC, UV, environmental, and water intrusion

- Validation Plan

Certifications

- Tested to meet UL 2580 and UN/DOT 38.3 certification requirements

- Utilizes UL 1642 certified cells